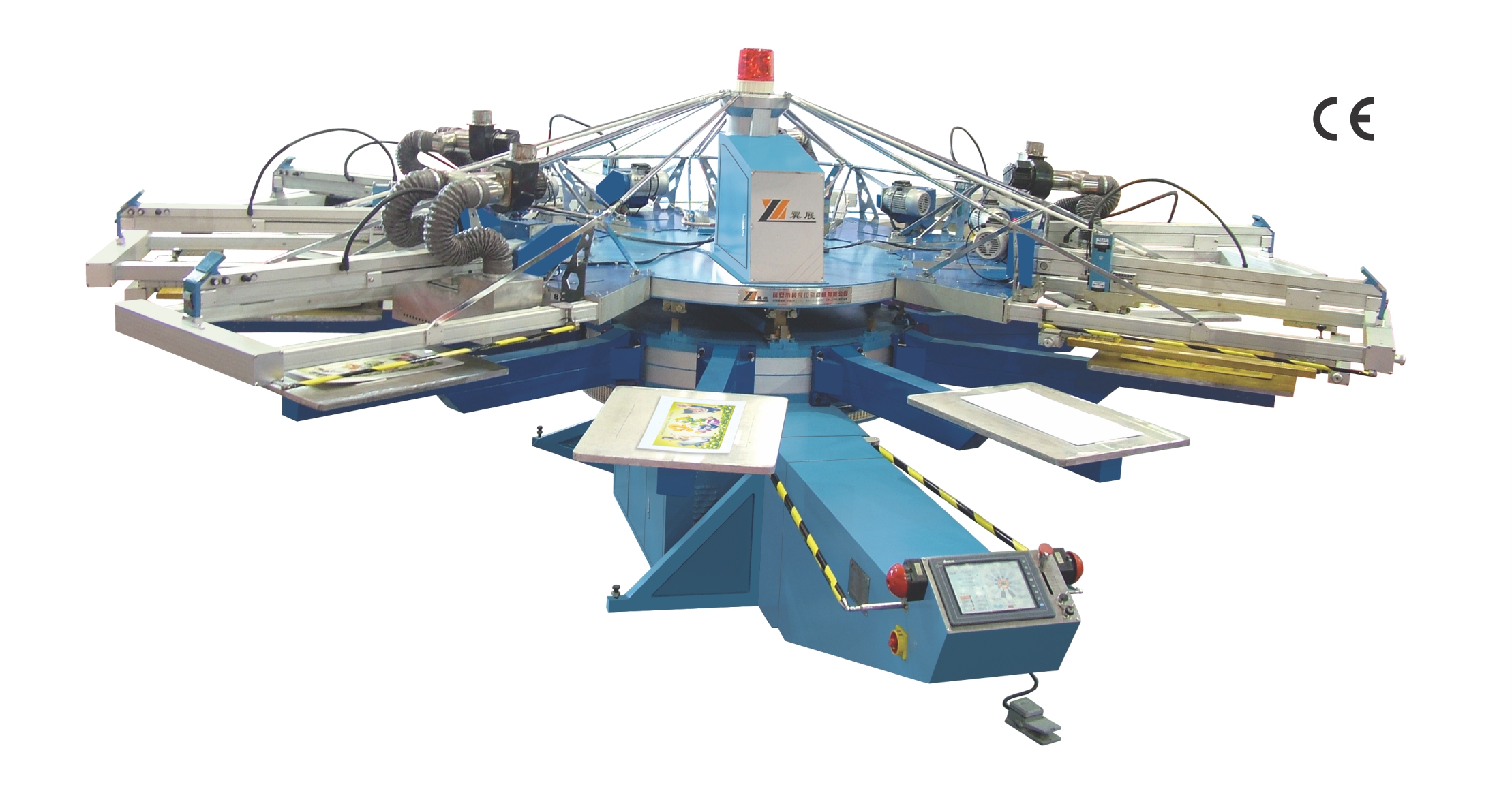

SPA Automatic Computerized UV Screen Printer

SPA丝网印刷机

SPA Screen printing machine

全自动多色圆盘UV丝网印刷机

Automatic UV Screen Printer

SPA series automatic computerizedUVscreen printer istheinnovativehigh-tech automatic UV printing equipments.Aimedfor higherproductionoutputand faster recovery of investments, it’sequippedwithintellegentmicro-processor,non-stop multicolor UV printing,instant UVinkdryerout,minimal maintenancerequired, but top UV print result,leading tothesuperiorprinter in any printworkshops. The printers not onlyapplies todohighcolor-to-color registrationprinting on garments and leatherssuchasnylon,tetoron, microfiber twill, satin,PVC and PU, but alsofittingonprintingstationery, handbags, gift boxes, such ascigaretteboxes,decorationboxes,metal sheets, hard & soft plasticboards-PVC, PP, PC,PET,EVA,APET,PETG--fabricboards, glassplates, and ceramicsetc inmulticolors.Withpatentsand CE certificate, State new products certificateofChinaapproved,themachinemustbe the leader and surely stand in forefront ofthescreenprintingindustry.

Features:

1, New-concept UV printingtechniques, 2 second UV inkdryoutfor 500x500mm printing area, non-stopmulticolor UV printing,innovativemachine design.

2, Instant UV dryer featuresHigh-speed insideaircirculation, automatic temperature control system, lowerelectricpowerconsumption but high curing efficiency.

3, Automatic screen positioningsystem withprecisionturntable, placidly & steady running, excellentlocalizer.

4, Every Squeegee and flood barcan be operated separatelybyindependent chopper, speed adjusted by frequency,slight air pressure.

5, Imported servo motor drivesystem makes itsrunningsmooth, precise and quick rotation; and central controlsystem withmultipleand inter changeble languages.

Workingprincipleandcharacteristics of UV oven:

I. UVcuring principle:

Adding aphoto initiator (orphotosensitizer) to aspecial formulation of the resin,after absorbing thehighintensity ultravioletlight in the UV curingequipment, the activatedfreeradicals are generated, thustriggeringpolymerization, cross-linkingandbonding reaction, so that the resinink/paintcan be changed from liquidtosolid in less than 1 second.

Ii. UVcuring lamp:

1. Atpresent, the light source ofUV equipment used inindustry is mainly gasdischarge lamp .Accordingto thepressure of the gas in thelamp cavity, it can be divided into lowpressure,medium pressure, high pressureand ultra-high pressure.

2.High-voltage lamps can generatecharacteristicultraviolet (UV), visible lightand infrared (IR) with strongradiation at 310nm,365nm and 410nm, among which365nm is the main peakwavelength, which is commonlyused in countries aroundthe world to solidify drybaths (UV lamp refers to thehigh-pressure lamp at365nm).Because thespectrum of365nm band is suitable forcommonly used photo curing ink/paint, itis necessaryto conduct photo fixationtest before selecting common UV photofixationequipment to check whether thewavelength of UV machine meets therequirementof photo fixation.

3. Thereasonable refraction of UVlight source and thestray light filtration of UVlamp tube are quite important,otherwise it willaffect the photo fixationeffect.

4.Generally, the power requiredby UV machine forink/paint fixation is80-120w/cm. Too high light settingenergy will cause thebrittlement of ink/paint,and too low light setting energywill not achieve thelight setting effect.

5. Atthe same time of sending outultraviolet UV lamp,also can produce a lot ofheat, make the body temperaturerising, so over the UVlamp light solid machineis equipped with convulsionsdevice is necessary, andthrough the ventilationpipe will be produced in theprocess of curing ozoneemitted to achievecooling, so as to adapt to the workof temperature or thincoating to demandhigher work..

Iii.Main features of our UV oven:

1. Theoven works as a whole, withbeautiful appearanceand light volume, saving space.

2.Equipped with professional lamptube power andimported light source reflectorfor maximum UV light refraction.

|

MODEL |

SPA |

|

Max curing size |

720*520mm |

|

Max speed |

900pcs/h |

|

Max. power |

5.5kw |

|

Work power |

2kw |

|

Voltage |

3ph, 380V, 50HZ |

|

Fan power |

370w |

SPA UV printing machine (air suck table):

SPA Automatic UV Screen Printer: